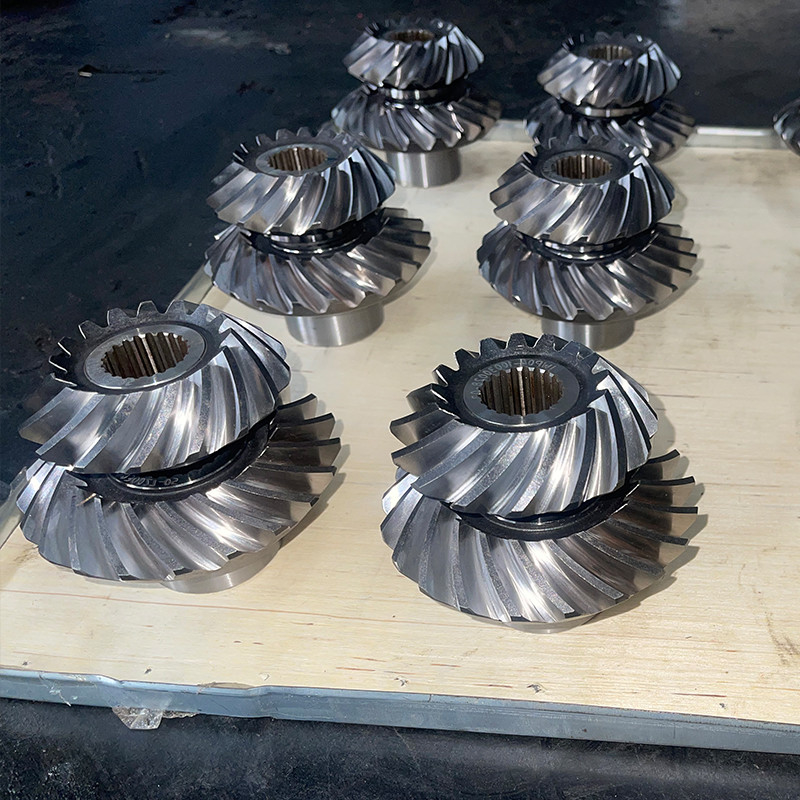

Hunan Ruida Heavy-duty Machinery and Equipment Co., Ltd. is a well-known enterprise located in LonglingIndustrial Park, Heshan District, Yiyang City. lts predecessor was Changsha Ruida Mold Equipment Co., Ltd. Sinceits establishment in October 2003, it has been dedicated to the research, development, and production of largemodule straight bevel gears and spiral bevel gears.

Our product range is extensive, with straight bevel gears covering a modulus range of 12 to 40mm and adiameter range extending from 200mm to 1700mm. For spiral bevel gears, the modulus range spans from 2 to45mm, and the diameter range is even wider, reaching from 50mm to 2300mm. These high-quality products arewidely used in various fields such as military, high-speed ralil, shipbuilding, petroleum, chemicals, cement,metallurgy, mining, and construction machinery.

In 2020, the company invested a whopping 6 milion USD to successfully introduce a high-precision spiral bevelgear processing production line, significantly enhancing our production efficiency and product precision. Currentlywe possess over 70 professional gear processing equipment, including lathes, planers, gear milling machines, gealgrinding machines, gear scraping machines, rolling inspection machines, and gear inspection centers. Theprecision reaches to above Grade 5(German DiN3965/86), fully demonstrating our exquisite skills in the field ofgear manufacturing.

Ruida Heavy Machinery boasts a team of experienced and skiled engineers and production technicians. Withtheir excellent professional knowledoe and rich practical experience, they ensure that our product auality remainsat the forefront of the industry. Additionally, the company has passed 1S09001 quality management systemcertification, and its auality inspection standards are strictly aligned with international standards, providingcustomers with even more reliable quality assurance

Over the years, Ruida Heavy Machinery has alwavs adhered to the customer-centered business philosophy.Our products are not only sold wel throughout China but also exported to many countries and regions such as theUnited States, the United Kingdom, Australia, Southeast Asia, and Africa, enjoying widespread popularity and trustamong customers. ln the future, we will continue to adhere to the principle of excellence and quality first, providingour customers with even more high-guality products and services. iointly creating a brighter future.

| Hardness: |

HB220-280, HRC45-62(Customizable) |

Direction: |

Based On Drawings |

| Teeth Number: |

Based On Drawings |

Tooth Profile: |

Based On Drawings |

| Material: |

Carbon Steel, Alloy Steel, Etc.(Customizable) |

Heat Treatment: |

Carburizing And Quenching,Nitriding Quenching, Induction Hardening, Quenching And Tempering(Customizable) |

| machinery test report |

Provided |

video outgoing-inspection |

Provided |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!