Hunan Ruida Heavy-duty Machinery and Equipment Co., Ltd. is a well-known enterprise located in LonglingIndustrial Park, Heshan District, Yiyang City. lts predecessor was Changsha Ruida Mold Equipment Co., Ltd. Sinceits establishment in October 2003, it has been dedicated to the research, development, and production of largemodule straight bevel gears and spiral bevel gears.

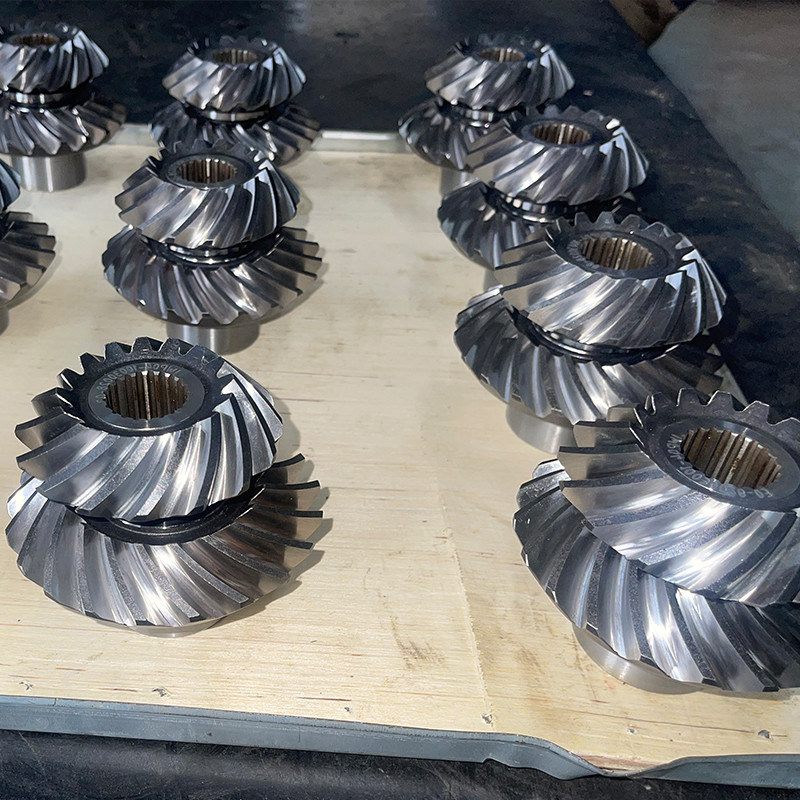

Our product range is extensive, with straight bevel gears covering a modulus range of 12 to 40mm and adiameter range extending from 200mm to 1700mm. For spiral bevel gears, the modulus range spans from 2 to45mm, and the diameter range is even wider, reaching from 50mm to 2300mm. These high-quality products arewidely used in various fields such as military, high-speed ralil, shipbuilding, petroleum, chemicals, cement,metallurgy, mining, and construction machinery.

In 2020, the company invested a whopping 6 milion USD to successfully introduce a high-precision spiral bevelgear processing production line, significantly enhancing our production efficiency and product precision. Currentlywe possess over 70 professional gear processing equipment, including lathes, planers, gear milling machines, gealgrinding machines, gear scraping machines, rolling inspection machines, and gear inspection centers. Theprecision reaches to above Grade 5(German DiN3965/86), fully demonstrating our exquisite skills in the field ofgear manufacturing.

Our products have been exported to abroad for more than 15 years and 40+ countries,Our products are highly favored by customers at home and abroad.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!