Product Description:

Product Description

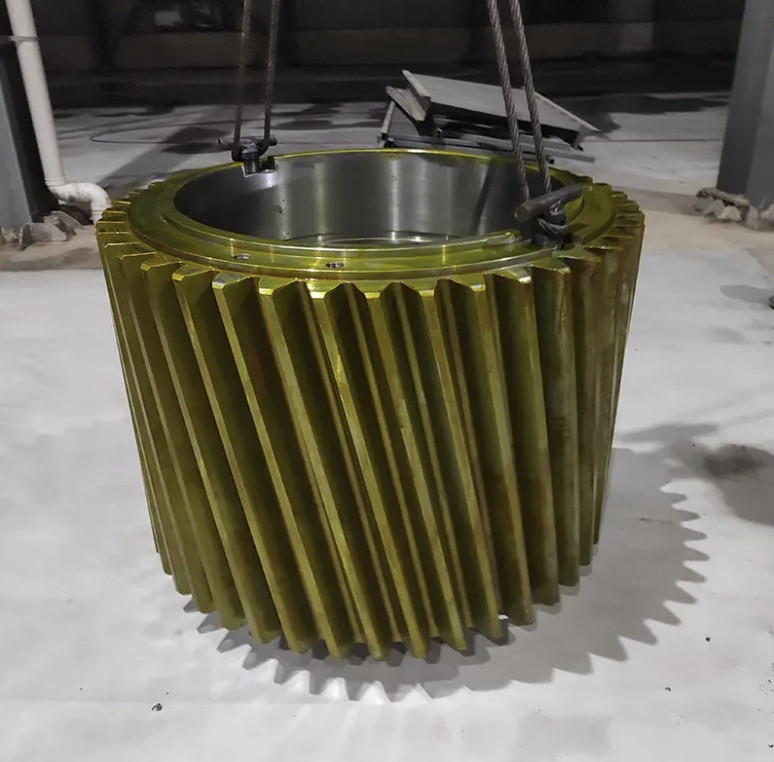

Our product, called OEM custom rotary kiln steel ball mill cnc lathe processing cement grinding helical gear, is a high-quality gear designed to meet our customer's needs. With our advanced technology and experienced team, we are capable of producing large forged and cast gears according to the customer's drawings.

We understand that each customer has unique requirements, and to meet those needs, we offer a range of customization options. These options include gear grinding, surface hardening, carburizing and quenching, nitriding and quenching, and more. Our aim is to deliver a product that meets our client's needs and exceeds their expectations.

Features:

One important process in gear manufacturing is internal gear machining. This involves the use of CNC gear shaping machines to shape the internal gears. CNC machines ensure precision and accuracy in the gear teeth and surface roughness. This is crucial because the performance and lifespan of the gears depend on the accuracy of their shape and surface finish.

The ultimate goal of internal gear machining is to ensure that the gears fit perfectly with other components, such as the large ring gear or gear shaft. The precise shape and surface finish of the gears are crucial in achieving this goal. Any errors or inaccuracies can cause the gears to not fit properly, resulting in suboptimal performance or even damage to the machine.

Therefore, it is essential to use CNC gear shaping machines to produce accurately shaped internal gears with the desired surface roughness. When internal gear machining is done effectively, it can help ensure that the gears will function smoothly and reliably, allowing the machinery to flourish and perform at its best.

Technical Parameters:

| Product Attribute |

Value |

| Product Name |

Transmission Gear |

| Type |

Manual |

| Application |

Automotive Industry |

| Color |

Silver |

| Shape |

Cylindrical |

| Material |

Metal |

| Size |

Standard |

| Durability |

High |

| Efficiency |

High |

| Installation Method |

Bolt-on |

| Maintenance |

Regular Lubrication |

| Product Type |

New Product 2022 |

| Additional Feature |

Non-standard gear |

Applications:

Frequently Asked Questions (FAQ)

Common Problems and Solutions

Can Your Products Be Customized?

Yes, most of our products are non-standard customized parts that can be tailored according to the drawings provided by customers.

What Is the Shipping Time?

The delivery time is determined by the complexity of your product. The general product cycle is 70 days, but specific needs can be negotiated between both parties.

Can You Add Our Company Logo on the Products?

Yes, we can add your company logo to the product and packaging if you meet our MOQ (Minimum Order Quantity).

How Do You Guarantee the Quality of Your Products?

We conduct comprehensive quality inspections on every product before shipment. We also send photos and videos of the quality inspection report to ensure product quality.

How Do You Ensure the Accuracy of Product Size?

Before shipment, we measure every data in the drawing to ensure the size of the product is accurate. We also send the size inspection report and inspection photos to our customers.

How Do You Package the Product?

We design suitable packaging for each product according to its shape, size, and use to avoid rust and damage during transportation.

Customization:

Support and Services:

Our Transmission gear product technical support and services include:

- Expert troubleshooting and diagnosis of product issues

- Assistance with product installation and setup

- Regular maintenance and performance checks

- Access to product manuals and documentation

- Repairs and replacements of faulty parts

- Product upgrades and customization options

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!